Long story short: In short, ceramic coating gives your bike strong protection. It keeps the paint safe from scratches, dirt, and weather, so your bike looks new for longer. Its UV resistance also helps stop fading. This guide covers the basics of bike ceramic coating.

As more people buy motorcycles in India, ceramic coating is becoming more popular. It not only improves your bike’s appearance but also gives it long-lasting protection.

This article will help you decide if ceramic coating is a good choice for your bike in India. We’ll go over the benefits, possible downsides, and important things to think about, like cost, how it’s applied, and maintenance.

Our goal is to give you the information you need to choose the right ceramic coating for your bike.

Key takeaways

- Ceramic coating gives your bike strong, lasting protection from things like dirt, acid rain, and UV rays. It also makes it easier to keep your bike looking clean and new.

- High hardness ratings like 9H or 10H in India mean the coating resists scratches well. However, how well it works also depends on how it is applied and how well you maintain it.

- Getting a professional to apply the coating means the surface is prepared well, the right products are used, and the process is done carefully. This usually makes the coating last longer and often comes with a warranty, which many DIY options do not offer.

- To keep the coating working well and looking shiny, wash your bike with pH-neutral shampoo, dry it gently, and use booster sprays. If you skip regular care, the protection will not last as long.

- Be discerning about product claims and differences. Not all coatings are the same, and terms like “lifetime protection” or “scratch-proof” can be misleading. Always verify product certifications, check reviews, and avoid very cheap or poorly labelled options.

What is a ceramic coating for bikes?

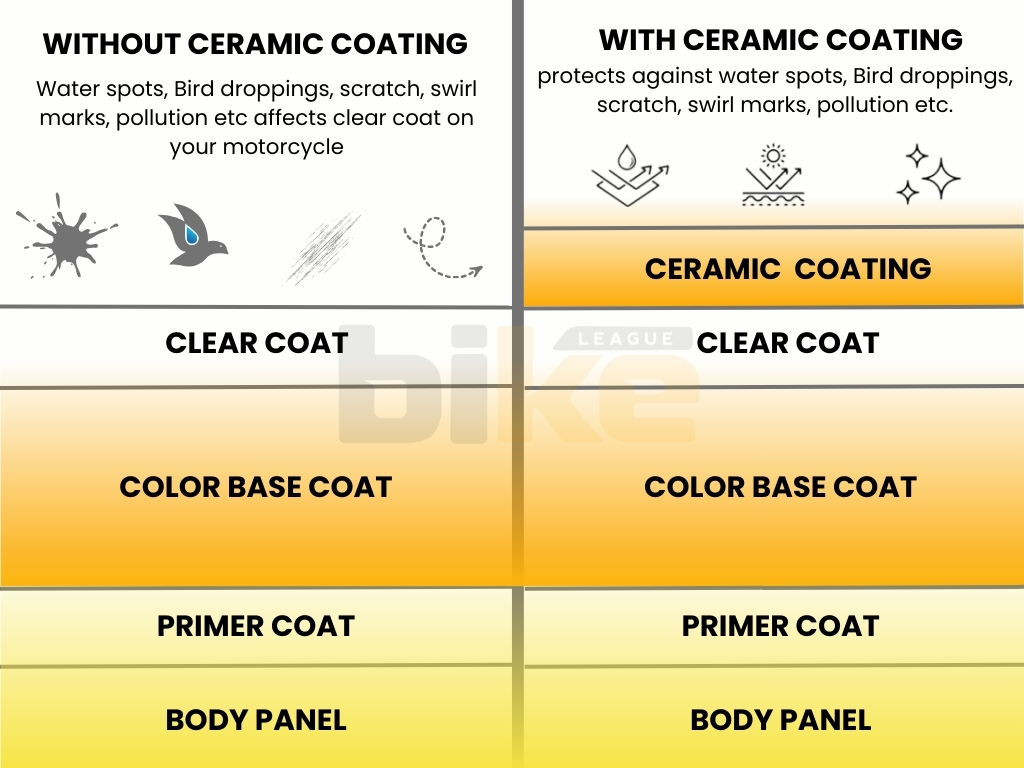

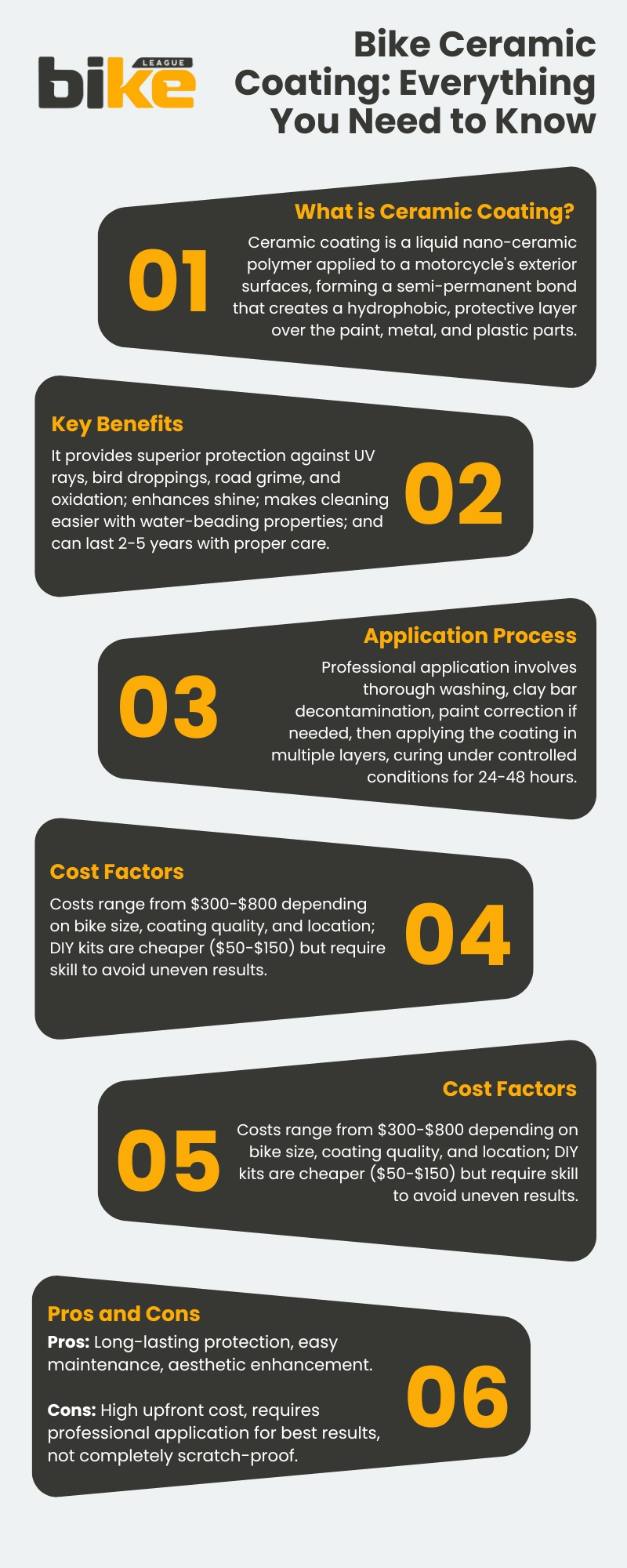

Ceramic coating is a type of liquid polymer, which is a chemical compound made up of long repeating molecules. This polymer is applied to your bike’s exterior surfaces, such as the paint. Once applied, it bonds to the surface and forms a protective barrier that shields against damage from ultraviolet (UV) rays (from sunlight), acid rain, dirt, and grime.

Ceramic coating gives your bike long-lasting protection and a shiny finish, helping it look new for longer.

The main reason to use ceramic coating is to protect your bike’s paint, make it easier to clean, and improve its appearance.

What is Hardness in Ceramic Coatings?

In ceramic bike coatings, “hardness” refers to how well the coating resists scratches, abrasions, and other forms of physical damage. This crucial property provides:

- Scratch Resistance: A higher hardness rating indicates better resistance to scratches and abrasions

- Durability: Harder ceramic coatings are more durable, providing long-lasting protection against wear and tear.

- Environmental Protection: Hard ceramic coatings offer superior protection against UV rays, oxidation, and chemical contaminants.

- Ease of Maintenance: A hard ceramic coating creates a smooth surface, making cleaning easier.

- Longevity: Harder coatings generally last longer, reducing the need for frequent reapplications.

Hardness can be measured in different ways:

- scratch hardness

- indentation hardness

- rebound hardness.

A coating’s hardness depends on its flexibility, strength, toughness, stress handling, and ability to return to shape.

Different Hardness Scale Types

Here, we will focus on Scratch Hardness, which is how well a material resists scratching or abrasion. These tests determine a material’s resistance to scratches and abrasions. Generally, there are three scales used for determining the hardness of minerals:

1. Mohs Scale

The Mohs scale ranks minerals by how easily they can be scratched by other substances. It ranges from 1 (talc, which is very soft) to 10 (diamond, the hardest natural material). The scale isn’t perfectly even, and most abrasive materials fall between 9 and 10.

2. Ridgway’s Scale

The Mohs scale can be modified by giving garnet a hardness of 10 and diamond a hardness of 15.

3. Wooddell’s Scale

Wooddell’s scale builds on Ridgway’s by using abrasion resistance and setting quartz at 7 and corundum at 9, which leads to a value of 42.4 for South American brown diamond bort.

Pencil Hardness Scale: How does it work

Coatings and films do not fit the Mohs, Ridgway, or Wooddell scales. That’s why ASTM created the Pencil Hardness Scale, which uses graphite pencils (usually rated 1-2H) to measure a film’s hardness.

The pencil hardness scale measures the hardness of graphite. The coatings industry uses this test to evaluate both clear and coloured coatings, especially to assess how well they’ve cured after heat is applied.

Pencils are graded on a scale from 10H (very hard) to 9B (very soft). ‘H’ stands for hardness, meaning the pencil makes lighter marks and is harder to wear down. ‘B’ stands for blackness, meaning the pencil is softer and makes darker marks. ‘HB’ means the pencil is both hard and black.

The scale ranges from 10H (the hardest) to 7H, with F in the middle. Softer pencils include HB, B, 2B, and 9B (the softest). Most people use the #2 (HB) pencil since it writes smoothly and leaves dark marks.

Measurement of Hardness in Ceramic Coatings

The pencil hardness test is the primary method for measuring ceramic coating hardness, especially in the automotive industry. This test uses pencils from 1H to 9H, with 9H being the hardest.

Other tests, such as Vickers and Knoop, use diamond tips for more precise results, but they are rarely mentioned in marketing.

The “H” rating for ceramic coatings differs from the Mohs scale, which measures mineral hardness from 1 (soft, like talc) to 10 (hard, like diamond). Mohs is sometimes used for comparison, but it doesn’t directly apply to ceramic coatings.

What are the common hardness values in the Indian Market for ceramic coating?

In India, ceramic bike coating hardness is typically measured using the pencil hardness test (ASTM D3363), not the Mohs scale. Common ratings include 7H, 9H, and 10H, each aimed at different price ranges and durability.

Main Hardness Ratings You’ll Find

- 7H:7H is found in budget, DIY, or graphene spray products and usually gives 1 to 2 years of solid bike protection.

- 8H: 8H is a mid-tier option that’s less common. It sits between affordable DIY coatings and professional 9H products, offering about 1.5 to 2 years of durability.

- 9H: 9H is the industry standard for professional ceramic coatings in India. It uses the hardest practical pencil grade and can last 2 to 5 years if applied and maintained well.

- 10H: 10H is mostly a marketing term for premium or graphene-enhanced ceramics. These claim better resistance to scratches and chemicals than 9H, cost more, and are meant to last over 3 to 5 years.

Hardness Claims to Watch Out For

- Claims such as 12H, 15H, 18H, or “diamond hardness” are marketing exaggerations and are not recognised by the pencil hardness scale.

- References to Mohs hardness for bike ceramics are misleading because automotive coatings are not tested using the Mohs mineral scale.

In India, a real 9H coating from a trusted brand or detailer is the practical standard if applied well. Only consider 10H products if the brand offers test data and fair pricing.

What is the step-by-step process of applying ceramic coating to bikes?

Applying ceramic coating might look easy, but it takes skill and attention to detail. Here’s a step-by-step guide to doing it right on your bike.

1. Initial Cleaning

The first step is to wash your bike well with a good pH-neutral shampoo. This removes dirt, grease, and other contaminants from the surface, ensuring the coating adheres properly.

2. Rinsing

Let the shampoo sit for a few minutes, then rinse the bike well with a hose or pressure washer. Make sure all soap is removed, especially from hard-to-reach spots, so the surface is clean for the coating.

3. Surface Preparation

This is the most important step. Professionals check the bike for any remaining dirt or grime and clean it again if needed, ensuring everything is spotless and dry.

To get the surface even cleaner, many professionals use a clay bar. They spray a lubricant, like a quick detailer, on part of the bike and move the clay back and forth to pick up any stuck-on dirt.

4. Paint Correction

Before applying the ceramic coating, professionals often address paint imperfections with a Dual Action (DA) polisher. This removes swirls and scratches, making the surface smooth and helping the coating look and work its best.

5. Application of Ceramic Coating

Once the surface is ready, the ceramic coating is applied. Professionals always follow the instructions for the specific product they’re using.

Usually, they work in small sections to make sure the coating goes on evenly and thinly. They use a clean pad or cloth and apply the coating in a crosshatch pattern to cover everything.

6. Buffing and Curing

After the coating is applied, it must cure as recommended by the manufacturer. This helps it bond well to the bike. Once it’s cured, professionals buff the surface with a clean microfiber cloth to bring out a shiny, protected finish.

Why is a professional application over DIY recommended for ceramic Coating?

You can buy DIY ceramic coating kits, but for the best results, it’s better to have a professional do it. Here’s why trusting a pro with your bike’s ceramic coating matters:

1. Expertise and Experience

Professional detailers know how to apply ceramic coatings correctly, from surface preparation to application and curing.

2. Superior Surface Preparation

Getting the surface ready is key to a good ceramic coating. Professionals clean and fix the paint first, because sealing in imperfections can make them stand out more.

3. Access to High-Quality Products

Professionals use top-quality ceramic coatings that protect better and last longer than most DIY products.

4. Proper Application Techniques

Applying ceramic coating takes skill and the right technique to get an even layer. Professionals do this in clean, controlled spaces and use specialised tools to ensure the coating looks good and protects well.

5. Controlled Curing Process

Curing is a key part of applying ceramic coating. Professionals know how long to keep the bike away from water and have the right setup to make sure the coating cures properly, which can be hard to do at home.

6. Long-Term Benefits and Warranty

When you get a professional application, it usually comes with a warranty. This covers problems like peeling or fading, which DIY kits might not. The extra durability and protection often make the higher cost worth it.

7. Avoiding Common Mistakes

DIY jobs can lead to mistakes such as uneven coating, not letting it cure long enough, or not cleaning the surface thoroughly. These issues can make the coating less effective or even harm your bike’s paint.

What are the things to consider for ceramic coating for bikes in India?

If you’re thinking about ceramic coating for your bike in India, here are a few things to consider:

- Climate and Environmental Conditions: India’s weather can be tough on bikes, with hot sun and heavy rains. Ceramic coatings help by protecting against fading and oxidation from UV rays, and their water-repelling properties make cleaning easier during the rainy season.

- Cost Considerations: The cost of ceramic coating in India depends on your bike’s size, the brand, and the coating’s quality. While it can be expensive at first, the long-term benefits and lower maintenance costs can make it a good investment. Professional applications cost more than DIY kits, but they usually last longer and work better.

- Maintenance and Aftercare:Even with ceramic coating, you still need to take care of your bike. Wash it regularly and avoid harsh cleaning methods. Some professional services also offer warranties and ongoing help.

What are the maintenance and aftercare tips for ceramic coating for motorcycles?

1. Initial Curing Period

Once the ceramic coating is applied, let it cure before washing your motorcycle. Avoid washing for the first 5 to 7 days. For the first 48 to 72 hours, keep your bike indoors or in the shade, away from water and humidity. If you notice dust, gently wipe it off with a dry microfiber cloth rather than using water. This helps the coating bond well and last longer.

2. Regular Washing Routine

To keep the ceramic coating in good shape, wash your motorcycle every two weeks. Use the two-bucket method: one bucket with pH-neutral, ceramic-safe shampoo, and another with clean water and a grit guard. Wash with a soft microfiber mitt (at least 300 GSM) and rinse it before each use. This routine helps protect your bike from India’s weather and road conditions.

3. Key washing tips

- Avoid washing your motorcycle in direct sunlight or when the surface is hot. Water dries too quickly in these conditions, leaving mineral spots.

- Pre-soak the motorcycle with foam to loosen brake dust, bugs, and road grime before washing the surface.

- Rinse off bird droppings, tree sap, or mud immediately with a detailing spray and blot gently—do not wipe harshly.

- Do not use automatic car washes with spinning brushes. They can cause tiny scratches and damage the coating.

4. Drying Techniques

After washing, dry your motorcycle right away using high-GSM microfiber towels (300 or higher) or an air blower. Do not let it air-dry, since hard water in India can leave spots. Avoid using regular towels, kitchen towels, or old T-shirts to prevent scratches and lint.

5. Booster and Top-Up Applications

To keep your coating working well, apply a ceramic booster every 3 to 6 months. Use an SiO2 or graphene-based booster on a clean, cool, and dry surface after washing. Spray it on, let it sit for 2 to 5 minutes, then buff with a microfiber towel to bring back water beading and shine.

Never use traditional wax or polish on ceramic coatings, as they can damage the coating. Only use booster sprays designed for ceramic coatings.

6. Common Mistakes to Avoid

| Mistake | Why It’s Bad | Solution |

|---|---|---|

| Washing too soon | Weakens coating bond | Wait 5-7 days |

| Using harsh detergents | Strips hydrophobic layer | Use pH-neutral shampoo only |

| Automatic brush washes | Creates swirl marks | Use manual or touchless wash |

| Drying with regular towels | Causes micro-scratches | Use 300+ GSM microfiber |

| Skipping booster applications | Coating loses effectiveness | Apply booster every 3-6 months |

| Leaving water spots | Mineral stains etch coating | Dry immediately, use filtered water if possible |

| Applying wax on top | Causes patchy results | Use ceramic boosters instead |

| Parking under trees | Tree sap and droppings damage coating | Use bike cover, clean contaminants ASAP |

7. Long-Term Maintenance Schedule

| Timeline | Action |

|---|---|

| First 48 hours | Avoid all water contact, park indoors |

| First 7 days | No washing, light dusting only with dry microfiber |

| Every 1-2 weeks | Regular wash with two-bucket method |

| Every 3-6 months | Apply ceramic booster spray |

| Annually | Professional decontamination wash with pH-neutral iron remover, inspect for reapplication needs |

8. Recommended Maintenance Products

For aftercare, choose a ceramic coating maintenance kit available in India. The Wavex Kit includes a 20-litre wash bucket with a grit guard, a dual-sided microfiber mitt, and a graphene-ceramic wash shampoo that cleans safely. Other good options are the Super Ceramic Coating After Care Kit, which includes pH-neutral shampoos and boosters, and Proklear CRC Ceramic Waterless Wash for quick touchups between washes.

What are the misleading Marketing and Product Selection Tips about ceramic coating for bikes in India?

1. Common Misleading Marketing Claims

- In India, marketing for ceramic bike coatings often overstates how long they last. Ads may promise “lifetime protection” or “5-10 year guarantees,” but in reality, these coatings usually last only 2-5 years, depending on quality, application, and maintenance in tough conditions.

- Words like “scratch-proof” or “bulletproof” can be misleading. These coatings only protect against small scratches and swirls, not damage from stones or falls.

- In the same way, claims that DIY kits give professional results are often exaggerated. Home applications often lack proper surface preparation, leading to poor bonding and early failure.

2. Red Flags in Bike Ceramic Products

- Watch out for vague “nano-technology” claims that don’t mention the SiO2 concentration. It’s better to look for products with 9H hardness or at least 70% silica.

- Kits that cost less than ₹2,000 often have sprays or waxes with the wrong labels, and these usually wash off quickly.

- If a product says “Imported from USA/Europe” but lacks lab accreditation, such as IATF 16949, or proof of independent testing, it may be hiding a low-quality formula.

- Service centres that offer “free lifetime maintenance” often use lower-quality products to increase their profits.

3. Product Selection Tips

- Verify Certifications: Check for certifications. Pick coatings that have proof of 9H pencil hardness, have passed 1000+ hour salt-spray tests, and have UV resistance ratings that work for India’s heat and humidity.

- Check Thickness: Professional bike coatings should be 1-2 microns thick after curing. Ask trusted detailers for before-and-after reports.

- Read Reviews Critically: Read reviews carefully. Focus on India-specific forums like Team-BHP or Reddit’s r/indianbikes instead of sponsored YouTube videos. Look for reviews with updates at least 6 months old.

- Test how water rolls off the surface after applying the coating: The water should run off at a contact angle of 110° or more, which is the angle at which the edge of a water droplet meets the surface. If water doesn’t bead well, the product isn’t working properly.

- Avoid bundle deals: like “ceramic + PPF + Teflon” combos. Mixing different systems makes them less effective, so it’s better to choose one proven system.

Common myths about ceramic bike coating in India

1. Is ceramic coating scratch-proof on bikes?

No, ceramic coating helps resist scratches but is not completely scratch-proof. It can protect your bike from minor scratches, but it will not prevent damage from larger impacts.

2. Does ceramic coating eliminate the need to wash my bike?

No, you still need to wash your bike. The coating helps repel dirt and water, so cleaning is easier, but you should still wash it regularly.

3. Will ceramic coating protect my bike from rock chips and dents?

No, ceramic coating will not stop rock chips or dents. It mainly protects your bike’s paint from sunlight, stains, and small scratches, but not from physical impacts.

4. Are all ceramic coatings the same in terms of quality and effectiveness?

No, not all ceramic coatings are the same. The quality and performance can differ, so getting it applied by a professional with good products gives you the best results.

5. Can ceramic coating turn a matte finish into a glossy one?

No, ceramic coatings designed for matte finishes will protect the surface without altering its appearance or feel.

6. Is ceramic coating a one-time permanent solution?

No, ceramic coatings are not a one-time fix. You need to maintain them with booster treatments and gentle washing to keep your bike protected and shiny.

7. Is ceramic coating worth the high cost compared to other options like Teflon?

Ceramic coating costs more than options like Teflon, but it offers better protection against sunlight and chemicals and is easier to maintain, making the higher price worth it.

Does ceramic coating for a bike affect bike insurance, claims, or resale value in India?

1. Insurance Impact

Ceramic coating is usually not seen as a structural or performance change by Indian insurance companies, so it does not affect your premium or coverage. Insurers are more concerned about changes like engine or exhaust upgrades. Cosmetic changes, such as ceramic coating, rarely lead to higher premiums or claim rejections. Still, it is a good idea to mention the coating when you renew your policy, since some insurers want to know about any changes, even small ones.

2. Claims Process

Ceramic coating does not change how insurance claims work in India because it only protects the paint and does not affect accident, theft, or damage checks. If you need to claim for paint repairs, the process is the same as usual. In some cases, the coating can even speed up assessments by keeping the paint in better condition. Insurers mainly look for changes that increase risk, and there are no reports of claims being denied because of ceramic coating.

3. Resale Value

Ceramic coating can help your bike keep its shine, protect it from the sun, and make it look newer for longer. It stops fading, scratches, and other damage that often happens on Indian roads, so your bike will look better to buyers. Good quality coatings, especially on expensive bikes, can even help you get a higher resale price.

How do regional factors like urban or rural settings, coastal humidity, pollution, and rural dust affect the choice and durability of ceramic coatings in India?

1. Urban Areas

In urban areas of India, ceramic coatings help protect car paint from pollution, smog, and acid rain that can harm it. Their hydrophobic qualities make cleaning easier and can keep the coating effective for 3 to 5 years with regular maintenance. For the best results, choose coatings with strong chemical resistance to guard against exhaust and road tar.

Rural Areas

In rural parts of India, unpaved roads and dust storms can quickly wear down car paint. Choose ceramic coatings that resist abrasion and have good self-cleaning abilities. While hydrophobic surfaces help keep dust off, washing your car often will prevent small scratches and help the coating last 2 to 4 years on rough roads. Thicker, more durable coatings are better than basic glossy ones.

Coastal Regions

In coastal regions, high humidity and airborne salt can accelerate paint corrosion and fading. Use ceramic coatings that repel salt and block moisture. Because humidity can reduce the coating’s water-repelling effect, apply booster treatments every few months to keep protection for 2 to 3 years. For chrome and exposed parts, pick marine-grade coatings.

Inland Regions

Inland regions with dry heat and UV exposure cause cracking and fading. Apply UV-blocking ceramic coatings to preserve color and prevent oxidation. Low humidity extends hydrophobic effects, ensuring 4-5 years of protection. Opt for heat-stable coatings designed for high temperatures.

Factor-Specific Impacts

- Coastal humidity: speeds up wear and needs strong moisture barriers.

- Urban pollution: calls for coatings with chemical resistance to make grime removal easier.

- Rural Dust: Needs abrasion resistance; improves dust shedding.

Benefits of bike Ceramic Coating

- Superior Protection Against Environmental Contaminants:Ceramic coating creates a strong barrier that protects your bike’s paint from dirt, acid rain, bird droppings, and tree sap, helping it stay in good shape over time.

- UV Ray Protection:Another benefit is protection from UV damage. In India’s strong sunlight, ceramic coatings help prevent fading and keep your bike’s colour looking fresh.

- Hydrophobic Properties:Because ceramic coatings are hydrophobic, water and other liquids bead up and roll off, making your bike easier to clean and reducing water spots.

- Enhanced Appearance:Ceramic coating gives your bike a shiny finish that deepens and brightens the colour, helping it look newer for longer.

- Long-lasting Protection:Unlike regular wax, ceramic coating protects your bike for years, so you don’t have to detail it as often.

- Resistance to Minor Scratches:Ceramic coatings aren’t completely scratch-proof, but they do help prevent minor scratches and keep your bike looking good. This is a big advantage of using ceramic coating.

- Ease of Maintenance:Another key benefit is that the smooth ceramic surface makes it harder for dirt to stick, so cleaning is easier, and your bike stays shiny.

Cons and Limitations of Ceramic Coating

- High Initial Cost:In India, ceramic coating for bikes usually costs between ₹2,500 and ₹15,000, depending on the brand and the size of your bike.

- Professional Application Required:To get the best results, it’s usually best to have a professional apply the coating because the process is detailed and requires skill.

- Not Completely Scratch-Proof:Ceramic coatings help protect your bike, but they don’t make it completely scratch-proof and can’t stop serious scratches.

- Ongoing Maintenance and Care:You’ll still need to clean your bike regularly and may need to reapply the coating to keep it working well.

- Potential for Misapplication:If the coating isn’t applied correctly, it can look uneven or even damage your bike, which is why professional help is important.

- Limited Durability:Ceramic coatings last longer than wax, but they aren’t permanent and might need to be reapplied, especially if your bike faces tough conditions.

Popular Ceramic Coating Brands in India

Several brands have gained popularity in the Indian market for their ceramic coating products:

- Labocosmetica

- Opti-Coat

- 3M Ceramic Coating

- WaveX Auto Care

- Gyeon Quartz

- CarPro

- Secret Surface Ceramic Coating

- IGL coatings

- Super Ceramic Coating

- DTK Kerala

- Ceramic Pro

These brands offer a range of products and services for all kinds of needs and budgets, so bike owners can find the right option for them.

FAQ about ceramic coating for bikes in India

1. How long does ceramic coating last on a bike in India?

The longevity of ceramic coatings varies widely, ranging from 6 months to several years, based on product quality and maintenance. With proper care, high-quality coatings can last 2-5 years in Indian conditions.

2. What is the cost of ceramic coating for bikes in India?

The cost of ceramic coating for bikes in India can range from ₹2,500 to ₹15,000 or more, depending on factors such as the coating brand, bike size, and service provider.

3. Is ceramic coating worth the investment for bikes in India, especially for those under 2 lakh INR?

The value of ceramic coating depends on the bike’s value and the owner’s priorities. It may not be cost-effective for bikes under 2 lakh INR. Still, it can be beneficial for those seeking aesthetics and long-term protection.

4. How does ceramic coating compare to traditional waxing or paint protection film (PPF)?

Ceramic coating provides longer-lasting protection and a more durable finish than conventional waxing. Still, it offers less scratch protection than PPF. It is easier to maintain and enhance aesthetics than PPF.

5. Can I apply a ceramic coating or hire a professional?

Ceramic coatings should be professionally applied for the best results. Experts have the skills, tools, and controlled conditions needed for proper preparation and application, ensuring the coating’s effectiveness and durability.

6. How should I maintain my bike after applying ceramic coating?

Maintenance of a ceramic-coated bike involves:

- Regular washing with pH-neutral shampoos.

- Avoiding abrasive cleaning methods.

- Periodic reapplication of a ceramic boost spray.

It’s essential to follow the manufacturer’s care instructions.

7. Will ceramic coating protect my bike from scratches and UV damage in India’s climate?

Ceramic coating provides excellent protection for bikes from UV rays, helping to prevent paint fading and oxidation. This is particularly beneficial in India’s sunny climate. While it offers some resistance to minor scratches, it’s not entirely scratch-proof.

8. How does ceramic coating affect matte or custom paint finishes?

Ceramic coating can alter the appearance of matte finishes, potentially adding a glossy effect. For custom or matte paint jobs, it’s crucial to use specialised ceramic coatings designed for these finishes or consult a professional to maintain the desired look.

Here are some related articles from our team

- Bike coating – Choose the Right Coating for You

- Nano Coating for Bikes: Less Wash, More Ride

- Bike insurance tips in India – Tips to get a lower premium

- Bike wash – Different types, procedures, precautions, FAQ

- Diesel Wash For Bike: Is It Good or Bad

Conclusion

Ceramic coating provides bikes in India with strong protection against the elements and enhances their appearance, which is why many bike lovers choose it. It’s easy to maintain and lasts a long time, but you should also think about the higher upfront cost, the need for a professional application, and regular upkeep.

As new ceramic coating options emerge, bike owners should consider the pros and cons and choose the option that best fits their needs and budget. For some, regular waxing might be better. But if you’re ready to invest, ceramic coating can give your bike great protection and a lasting shine on Indian roads.

If you have questions or want more information, email us at bikeleague2017@gmail.com or leave a comment below. We’re always here to help. Also, follow Bikeleague India on social media to stay updated!