Long story short: Let’s take a look at the different types of bike clutch, including hydraulic and wet clutches, along with their pros, cons, and some frequently asked questions.

Most riders are already familiar with clutches, since gear changes in manual bikes wouldn’t be possible without them. Thanks to new technology, there are now several types of clutches available, such as dry and wet clutches. Manufacturers focus on making gear shifts smoother and reducing the need for maintenance or repairs.

In this article, we’ll review the various types of bike clutches and examine their advantages and disadvantages.

Key Takeways

- A wet clutch is the most common type of clutch found in almost all motorcycles. As the name suggests, the same oil is used for the engine to soak the clutch.

- The slipper clutch allows the clutch to slip partially until the engine speed matches the vehicle’s speed. The primary function of a slipper clutch is to control the rear wheel of the bike during hard braking and downshifting scenarios.

- The primary advantage of a multi-plate clutch over a single-plate clutch is its high torque-transmitting capacity. A multi-plate clutch is smaller than a single-plate clutch for a given torque capacity.

- An electronic clutch (E-Clutch) is an advanced clutch system among various clutch types that automates clutch operation while maintaining the traditional gear-shifting mechanism.

What is a bike clutch?

The clutch is a critical component in a motorcycle’s transmission system. Its primary function is to temporarily disconnect the engine from the transmission and drivetrain system, allowing the rider to change gears smoothly. The clutch lever on the left handlebar connects to the circular clutch assembly. There are two main types of clutches: wet clutches, which use engine oil for cooling and lubrication, and dry clutches, which do not require an oil bath.

The connection between bike clutch and gearbox (transmission)

The clutch and gearbox work together to facilitate smooth gear changes. When the clutch lever is pulled, it disconnects the engine from the gearbox, allowing the rider to shift gears without damaging the transmission. Releasing the clutch gradually re-engages the engine with the gearbox, transferring power to the rear wheel.

Different types of bike clutch

1. Bike Wet Clutch

A wet clutch is the most common type of clutch found in almost all motorcycles. As the name suggests, the same oil is used for the engine to soak the clutch. This clutch’s primary benefits are its long life and efficiency. Another USP is that the power loss due to friction is negligible.

Motorcycle Examples

Pros of wet clutch

- Less wear and tear

- Longer life and efficiency

- Negligible friction and power loss

- Cheaper

- Quiet while in operation

Cons of wet clutch

- A slight loss in engine horsepower due to the rotation of the clutch in oil.

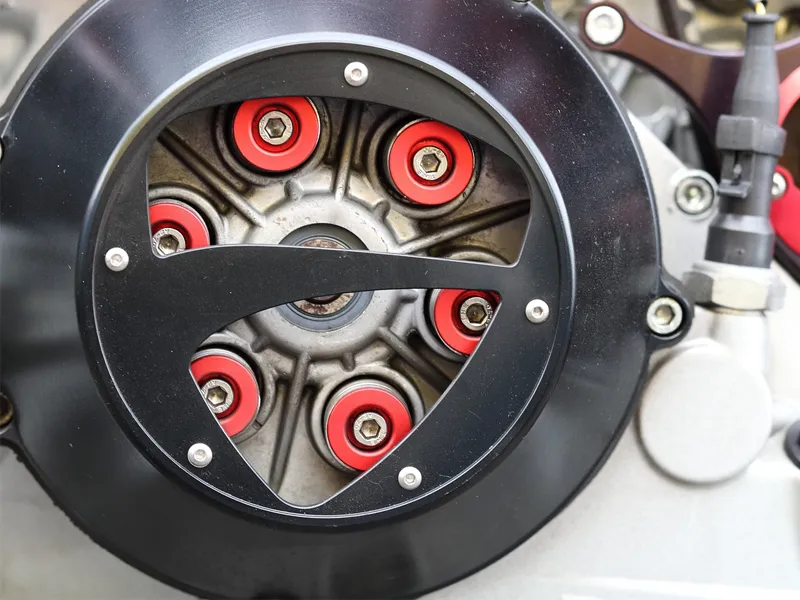

2. Dry Clutch

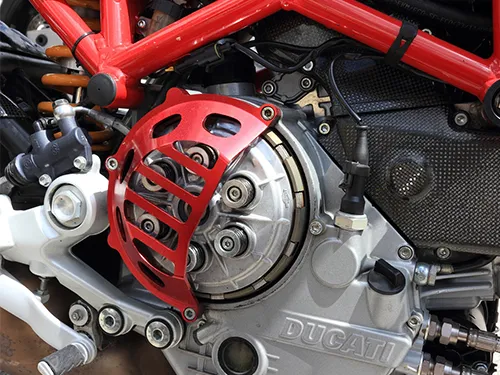

A dry clutch is one of the different types of bike clutches. The primary difference between a wet clutch and a dry clutch is that a dry clutch contains no oil and is entirely located outside the bike’s case. A dry clutch setup is mainly found in minimal motorcycle models. Ducati is one company that uses dry clutches.

Motorcycle Examples

Pros of dry clutch

- Easy to replace.

- Easy to use.

- No loss of horsepower.

Cons of dry clutch

- Overheating

- Shorter life

- Very noisy

3. Slipper Clutch

The slipper clutch (also known as a back-torque limiter clutch) is one of the different types of clutches that prevent engine over-revving and rear-wheel hop under challenging bike braking scenarios and aggressive gear downshifting. The slipper clutch allows the clutch to slip partially until the engine speed matches the vehicle’s speed. The primary function of a slipper clutch is to control the rear wheel of the bike during hard braking and downshifting scenarios.

In vehicles equipped with a standard clutch, the engine braking force is transmitted to the rear wheel via its chain drive, causing the rear wheel to wobble and potentially lose traction. Some models of KTM and Bajaj have slipper clutch equipped with the engine.

Motorcycle Examples

Pros of slipper clutch

- Prevents rear wheel lockup

- Absorbs engine braking force

- Ability to perform aggressive downshifts during cornering and emergencies.

- Reduces wear and tear on the engine and transmission

- Prevents accidental downshifts

- Excellent performance-wise

Cons of slipper clutch

- Mechanically complex technology

- Expensive

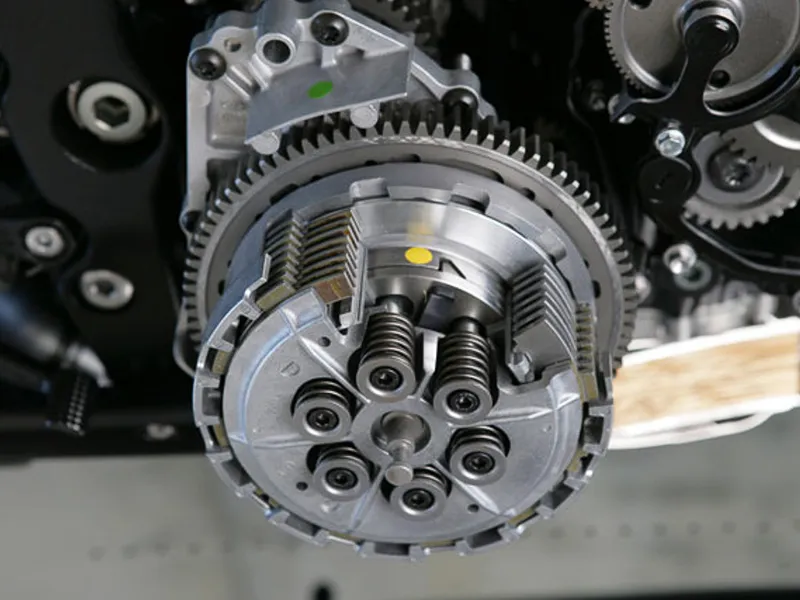

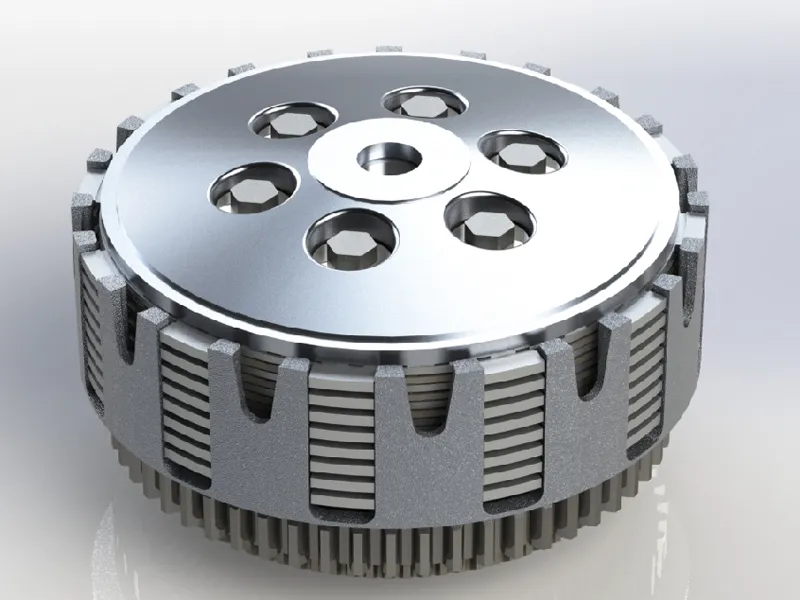

4. Multi-plate bike Clutch

The multi-plate clutch is the most common type of clutch used in motorcycles. It can be used both as a wet and dry clutch unit. These types of clutches utilise several interleaved driven and friction plates, all of which are placed within a standard hub. The primary advantage of a multi-plate clutch over a single-plate clutch is its high torque-transmitting capacity. A multi-plate clutch is smaller than a single-plate clutch for a given torque capacity. Hence, it is primarily used in compact vehicles, such as motorcycles.

Motorcycle Examples

Pros of Multi-plate clutch

- Ability to transmit a high amount of torque

- The smaller size compared to a single plate clutch

Cons of Multi-plate clutch

- Expensive

- Heavy

- Clutch engagement is not instantaneous

5. Centrifugal Clutch (Automatic Clutch)

Centrifugal clutches are used in mopeds and scooters, as the engine rpm defines the engagement or disengagement of the clutch. This clutch type works similarly to the Continuously Variable Transmission (CVT). It works on the principle of centrifugal force exerted on a revolving mass, which acts as an attractive force. This clutch is placed between the engine shaft and the transmission shaft. One side of the clutch is connected to the engine crankshaft, and the other is connected to the gearbox shaft, chain, or belt.

Motorcycle Examples

Pros of Centrifugal clutch

- Automatic and simple to use

- Low in price and less maintenance

- Prevents the engine from stalling

Cons of Centrifugal clutch

- Not able to transmit a considerable amount of torque

- Power loss due to friction and slipping

- Overheating issue

- Limited power transmission due to slippage

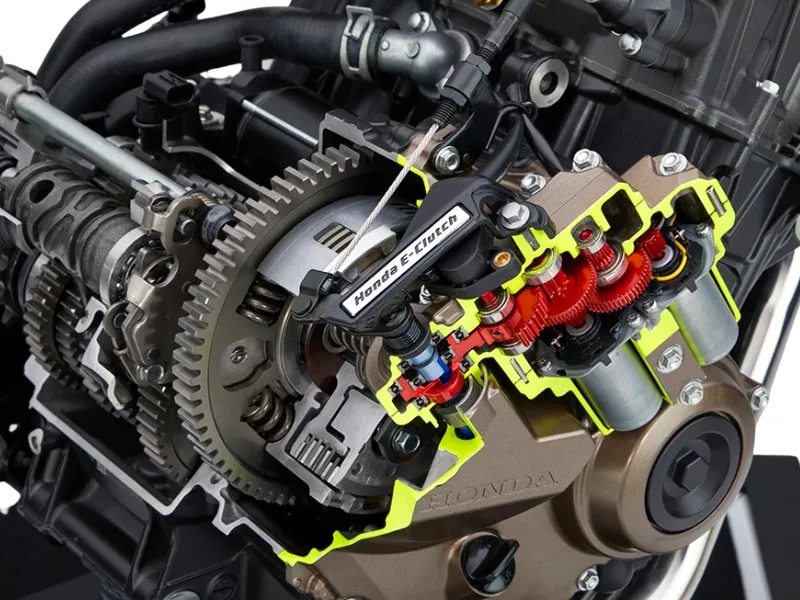

6. Electronic Clutch

An electronic clutch (E-Clutch) is an advanced clutch system among various clutch types that automates clutch operation while maintaining the traditional gear-shifting mechanism. This technology allows automatic clutch control during starting, stopping, and shifting, with the option for manual clutch operation when desired.

Motorcycle Examples

Pros of Electronic Clutch

- Ease of Use: Simplifies gear shifting without manual clutch control, making it nearly impossible to stall the engine.

- Flexibility: Offers the option for manual clutch operation, providing a balance between automatic and manual control.

- Convenience: Ideal for commuting and riders with hand strength issues, such as older individuals or those with arthritis.

Cons of Electronic Clutch

- Complexity: Increased complexity and weight can affect the bike’s performance and maintenance.

- Potential for Failure: More electronic components can fail, leading to potentially costly repairs.

7. Diaphragm Spring Clutch

The diaphragm spring clutch uses a single diaphragm spring to provide clamping pressure. This clutch type is typically found in heavy-duty motorcycles because it offers higher clamping pressure than coil springs. The diaphragm spring clamps in a full circle on the clutch plates, ensuring even pressure distribution and efficient engagement. This clutch type is more compact and lighter than traditional coil spring clutches.

Motorcycle Examples

Pros of Diaphragm Spring Clutch

- Compact Design: More compact and lighter, resulting in a smaller clutch housing and weight reduction.

- Consistent Pressure: Provides consistent pressure and smoother operation, enhancing the riding experience.

- Dual Functionality: The diaphragm spring acts as both the clamping spring and the release lever, reducing the number of parts needed.

Cons of Diaphragm Spring Clutch

- Cost: It can be more expensive to replace compared to coil spring clutches.

- Size Requirements: To achieve a higher coefficient of friction, the size and diameter of the diaphragm need to be increased, which can complicate the design.

8. Constant-Mesh Clutch

A constant-mesh clutch meshes all gears, allowing for smoother and quicker gear changes. This type of clutch is commonly used in modern motorcycles with advanced transmissions.

Motorcycle Examples

Pros of Constant-Mesh Clutch

- Smooth Gear Changes: Allows for quicker and smoother gear changes, enhancing the riding experience.

- Reduced Wear: Reduces wear on gears, leading to a longer lifespan for the transmission components.

Cons of Constant-Mesh Clutch

- Complexity: More complex and can be more expensive to repair due to the intricate design and precise engineering required.

9. Cable-Operated Clutch

The cable-operated clutch uses a cable mechanism to engage and disengage the clutch. The rider manually operates this clutch through a lever connected to the clutch cable. Cable-operated clutches are present in older bikes and classic motorcycle models. They are best for their simplicity and ease of maintenance.

Motorcycle Examples

Pros of Cable-Operated Clutch

- Lower Cost: Cable clutches are generally cheaper to purchase and maintain.

- Simple Maintenance: Maintenance tasks such as cable lubrication are straightforward and can be done easily by the rider.

- Adjustability: Riders can manually adjust the clutch engagement point to their preference, providing a customisable feel.

- Preferred by Some Riders: Some experienced riders, including professional racers, prefer the tactile feedback and modulation of cable clutches.

Cons of Cable-Operated Clutch

- Inconsistent Feel: Lever effort can vary with usage, wear, and cable stretching, often leading to heavier and less smooth engagement compared to hydraulic clutches.

- Frequent Adjustments Needed: Cable tension requires regular maintenance; as the clutch plates wear, slack must be adjusted manually for ideal operation.

- Prone to Wear and Breakage: Cables can fray, snap, or bind, especially if bent or routed poorly, and are vulnerable to corrosion and damage near hot engine or exhaust parts.

- Lack of Modulation and Adjustability: It’s harder to fine-tune the clutch engagement and disengagement points, and the actuation can feel less precise

10. Bike Hydraulic Clutch

Among the different types of bike clutches, the hydraulic clutch boasts smoother operation and reduced effort due to the use of hydraulic fluid. A hydraulic clutch system uses a fluid-filled reservoir attached to the bike’s clutch lever. When the lever is pulled, the fluid pressure is transmitted through a hydraulic line to a bike slave cylinder, which disengages the clutch. The fluid used in hydraulic systems is almost incompressible, ensuring efficient energy transfer.

Pros of Bike Hydraulic Clutch

- Ease of Use: Hydraulic clutches generally have a lighter pull, making them easier to operate, especially in heavy traffic. This reduces rider fatigue during long rides compared to other clutch types.

- Self-Adjusting: These systems are self-adjusting, meaning they automatically compensate for wear and tear, ensuring consistent performance.

- Low Maintenance: Hydraulic clutches are virtually maintenance-free, requiring only periodic fluid changes rather than regular cable lubrication.

- Smooth Operation: The hydraulic system provides smoother and more precise control over the clutch, which can benefit fine-tuning and modulation.

Cons of Hydraulic Clutch

- Higher Initial Costs: Hydraulic clutches’ initial cost and installation are higher than those of cable-operated systems.

- Complex Maintenance: While they require less frequent maintenance, when issues do arise, such as fluid leaks or seal damage, repairs can be more complex and costly.

- Fluid Management: Requires regular fluid change as it can absorb moisture, affecting performance.

- Engagement Feel: Some riders find the engagement point of hydraulic clutches less intuitive and harder to get used to.

11. Coil Spring Clutch

Coil spring clutches, commonly found in road bikes, use multiple coil springs to provide the necessary tension for clutch engagement. These springs are positioned between the diaphragm springs and help engage and release the clutch during gear changes. Adjusting the force of the coil springs modifies the clutch’s performance.

Motorcycle Examples

Pros of Coil Spring Clutch

- Consistent Performance: Coil springs provide consistent tension, ensuring reliable clutch operation.

- Widely Used: They are commonly used on road bikes and general motorcycles.

Cons of Coil Spring Clutch

- Maintenance Required: The springs can wear out over time and may need to be replaced.

- Not Ideal for High-Performance Applications: They may not provide the same level of performance as diaphragm spring clutches in high-torque situations.

Detailed comparison of different types of bike clutch

| Clutch Type | Lubrication | Actuation Method | Key Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Wet Cluth | Oil-Bath | Cable Or Hydraulic | Plates immersed in engine oil for cooling | Smooth, durable, quieter, longer life | Slight power loss due to oil friction |

| Dry Clutch | Air | Cable | No oil; plates run dry | Better power transfer | Noisy, wears faster |

| Slipper Clutch | Oil bath or dry | Cable or Hydraulic | Controls slip during aggressive downshifts | Prevents rear wheel lock, safer, smoother | More complex, costly |

| Multi-Plate Clutch | Usually wet | Cable or Hydraulic | Multiple friction plates stacked for more torque | Handles high power, smoother engagement | Larger size, complex design |

| Centrifugal Clutch | Usually dry | Automatic (RPM based) | Engages based on RPM; no clutch lever needed | Beginner-friendly, easy operation | Limited control at high speeds |

| Electronic Clutch | Varies | Electro-hydraulic/Electric | Clutch engagement controlled electronically | Precise, automatic, less rider effort | Expensive, complex maintenance |

| Diaphragm Spring Clutch | Usually wet | Cable or Hydraulic | Uses diaphragm spring for even pressure | Compact, consistent pressure, reduced effort | Sometimes harder to actuate |

| Constant-Mesh Clutch | Usually wet | Cable or Hydraulic | Gears always mesh, clutch used to engage/disengage | Smooth shifting, durable | Complex, higher cost |

| Cable-Operated Clutch | Varies | Mechanical cable | Mechanical cable actuation | Simple, cheap, reliable | Needs frequent adjustment |

| Bike Hydraulic Clutch | Uses fluid | Hydraulic fluid | Fluid actuated, self-adjusting | Lighter lever, consistent feel | Requires maintenance, bleeding |

| Coil Spring Clutch | Usually wet | Cable or Hydraulic | Coil springs apply pressure to clutch plates | Simple, affordable | Less common in modern bikes |

FAQ related to different types of bike clutch

1. What are the benefits of a wet clutch over a dry clutch?

Wet clutches are more durable, quieter at idle, and can sustain more abuse compared to dry clutches. They are better suited for stop-and-go traffic and general road use.

2. Which clutch is the best for racing or performance bikes?

The slipper clutch is the best, as it can withstand aggressive downshifts, higher engine braking force, and rear wheel lockup than other bike clutch types.

3. Is partial or half-clutch riding good for the transmission?

No. Half-clutch riding can cause premature wear to parts and damage to the transmission.

4. Does frequently using a bike’s clutch affect mileage?

Yes. Using the clutch frequently while driving increases fuel consumption. The engine consumes more fuel when the clutch is pressed, rather than when a gear is engaged.

5. Does bike clutch wear affect mileage?

Yes. As the motorcycle’s clutch starts to wear, it slips to other gears, affecting fuel efficiency.

6. What is the difference between a bike hydraulic clutch and a cable-operated clutch?

A hydraulic clutch operates using hydraulic fluid, providing smoother and more precise control over the bike. It is often found on touring and heavy-duty bikes. In contrast, a cable-operated clutch relies on a mechanical cable mechanism, which is more common in older and classic models.

7. What are the benefits of a wet clutch over a dry clutch?

Wet clutches are more durable, quieter at idle, and can sustain more abuse compared to dry clutches. Stop-and-go traffic and general road use can cause motorcycles to experience wet clutches.

8. How does a coil spring clutch differ from a diaphragm spring clutch?

A coil spring clutch, commonly found in road bikes, uses multiple coil springs to provide tension. On the other hand, a diaphragm spring clutch uses a single diaphragm spring. Heavy-duty motorcycles utilise this type of bike clutch due to its consistent pressure distribution.

Other related articles from Bikeleague India

- Bike wash – Different types, procedures, precautions, FAQ

- Braking in motorcycle – All expert tips for bikers

- Motorcycle helmet in India – All in one buying guide

- motorcycle swingarm varieties exploring different types/

- The Ultimate Guide to Motorcycle Suspension: Everything You Need to Know

Conclusion

We’ve covered the main types of bike clutches, their pros and cons, and answered some common questions. If you have more questions, feel free to email us at bikeleague2017@gmail.com or leave a comment below. We’re here to help. You can also connect with us on Bikeleague India’s social media platforms.